world of industries 3/2017 (EN)

- Text

- World

- Industries

Control technology that

Control technology that moves aircrafts on the ground safely Continuously increasing air traffic volumes are a constant challenge for ground operations at the airports. The aircraft tow tractors from the company Goldhofer, fitted with STW’s control technology are a big help - providing safe, economical and flexible movement of the aircrafts on the ground. At “Inter Airport Europe 2015”, the world’s largest trade fair for airport equipment and technology, the company ‘Goldhofer’ presented the ‘AST-2P/X’, its new generation of high speed aircraft towing tractor. Using the AST-2P/X, a wide range of aircrafts from Embraer170 up to the Boeing B777-300ER and the Airbus A340 can be moved. The AST 2 of the fourth generation is characterized by a new, compact and modular vehicle concept. The hydrostatically driven steering mechanism and axle delivers optimum traction, even in case of low superimposed load. For airport management companies that require the towing tractors, they can choose between two engine powers for the vehicle which offers a 3-circuit braking system which optimally distributes the braking force for maximum stability and safety. The engines fulfill all required international emission stan- dards, Euro IIIa or IVf. The airplane power supply during towing operation is ensured via a Ground Power Unit (GPU), which can be retrofitted into each of these vehicles. Ground operations at airport entail a lot of waiting periods. The automatic start-stop function which is installed in the AST 2 provides a high cost savings potential. This function provides not only a substantial reduction in the diesel consumption but it also brings down the maintenance costs, as maintenance intervals depend directly on the operating hours. These factors help in reducing the “Total Cost of Ownership” (TCO). Drive Line Controller (DLC) The AST-2P/X has a diesel-hydraulic drive system as its central component. It is built on a pump and two hydraulic engines, which drive a differential steering axle via a summation gearbox. The pump and the engines are controlled with electrical proportional adjustment. The energy for the drive system is supplied by a 231 KW (optional: 283 KW) Cummins QSL9 diesel engine. The drive system is controlled by the DLC or the Drive Line Controller. The DLC is responsible for managing the entire drive and limiting the tensile forces depending on the type of the aircraft. During the towing process, only a limited tensile force may be applied to the nose wheel (Fig. 1). The tensile force limitation in the DLC is realized through a dynamic, high pressure regulation, which again varies from aircraft to aircraft. In addition, the DLC is also responsible for the automatic start-stop function. ESX-3XL – Freely programmable control unit by STW HANNOVER MESSE

Dynamic Solutions Expertise. For a Dynamic Industry. Whether hose lines for hydraulic oils and other media, vibration isolation systems, drive belts, pneumatic air actuators for machine and plant engineering, or many more solutions – as a leading development partner for high-quality plastic and rubber components, we offer dynamic solutions expertise for a dynamic industry. Visit us in Hall 6, Booth F18 Hannover Messe 24. - 28. April 2017 www.contitech.de Industrial Competence Worldwide

- Page 1 and 2: www.world-of-industries.de Hannover

- Page 3 and 4: WELCOME Welcome to the world stage

- Page 5 and 6: 44 52 36 BLOCK I/O MODULES SIMPLIFY

- Page 7 and 8: NEWS AND MARKETS 4 5 Your Global Au

- Page 9 and 10: NEWS AND MARKETS politicians and Tr

- Page 11 and 12: NEWS AND MARKETS tomorrow runs with

- Page 13 and 14: If you want to build the world’s

- Page 15 and 16: NEWS AND MARKETS Poland’s Morawie

- Page 17 and 18: NEWS AND MARKETS IMI Precision Engi

- Page 19 and 20: MACHINE ELEMENTS 01 Igus bearings a

- Page 21 and 22: MACHINE ELEMENTS ence from pilot pr

- Page 23 and 24: Brake Technology 4.0 at Hannover Me

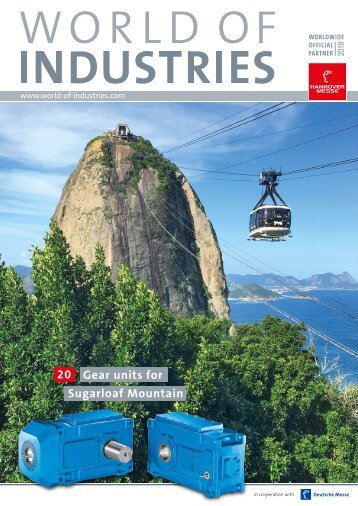

- Page 25: MACHINE ELEMENTS 01 In the Batumi t

- Page 29 and 30: MACHINE ELEMENTS IEC 61508-3, 7.4.2

- Page 31 and 32: DRIVE TECHNOLOGY Basic data for Nor

- Page 33 and 34: PRODUCT NEWS Fan blades inspired fr

- Page 35 and 36: Floating caliper brake with one-pie

- Page 37 and 38: SENSORS AND MEASUREMENT Both RFID b

- Page 39 and 40: CONTROL AND DRIVE TECHNOLOGY onstra

- Page 41 and 42: CONTROL AND DRIVE TECHNOLOGY Handof

- Page 43 and 44: INDUSTRIAL COMMUNICATION 01 The Pro

- Page 45 and 46: COMPONENTS AND SOFTWARE integrated

- Page 47 and 48: COMPONENTS AND SOFTWARE Industrial

- Page 49 and 50: PRODUCT NEWS Modular platform of au

- Page 51 and 52: COMPRESSED AIR NEWS Compressed Air

- Page 53 and 54: ComVac. How can we combine innovati

- Page 55 and 56: 02 Real-time data monitoring is per

- Page 57 and 58: COMPRESSED AIR NEWS New energy-effi

- Page 59 and 60: CONTENT - MARKETING AT ITS BEST BE

Inappropriate

Loading...

Mail this publication

Loading...

Embed

Loading...