world of industries 3/2017 (EN)

- Text

- World

- Industries

HANNOVER MESSE

HANNOVER MESSE designations of a component in various documents are as much a thing of the past as time-consuming comparisons of load and field device listings that were created at the start of a project,” reported Quante. “It’s worth rethinking” Function-oriented assembly formation is now an important focus for the engineering process because it creates reusable standards which significantly minimize errors and coordination work. The assemblies are formed from individual functions with underlying circuit components or circuit diagram pages. According to the administrator Möller, the structural creation of functions requires another work method, but it’s worth rethinking. He explained: “Functional orientation saves a significant amount of time and divides the sub-systems very clearly to boot.” Clean break with the introduction of the new system “We have made a complete clean break with the introduction of the new system. This means that we still use the previous tool for old projects, but design all new projects with Engineering Base,” explained Thomas Quante. In doing so, Rippert derives the new standards from existing projects. However, the circuit components and functional assemblies are still always checked again before storing these standards in EB’s database. Thus users can always rely on a high quality standard also. Rippert implemented the conversion gradually for small groups of employees. “The switch was not all plain sailing because the new system signifies a completely different approach, but we have recognized EB’s potential and are coming ever closer to our goal of seamless consistency with it,” reported Thomas Möller. Data consistency at all times Currently, the engineers are working on the EB link to the also new ERP system. The aim is to be able to respond swiftly and comprehensively to necessary adjustments and ensure data consistency at all times. Additional attributes were developed for material types to adapt the EB device master data to the ERP database. In this manner, the search structure remains clear in both systems. Rippert’s I&C Design department will now gradually adjust the new system to its own specific requirements. Knowing the possibilities of Engineering Base, the I&C Design experts want to make the most of it. “EB’s flexibility is open to further requests and requirements on our part and is thus also future-proof in the longer term. Its consistency is already exceptional now,” concluded Thomas Quante. Photographs: Rippert Anlagentechnik, Germany www.aucotec.com Power range in the cabinet for four booths; project structure in Engineering Base (EB) About Aucotec Aucotec AG has over 30 years of experience in developing engineering software for the entire life cycle of machines, plants and mobile systems. The solutions range from flow diagrams via control and electrical engineering for largescale plants to modular harness design in the automotive industry. Aucotec software is in use all over the world. In addition to its headquarters in Hanover, Aucotec operates six further sites in Germany as well as subsidiaries in China, South Korea, France the United Kingdom, Italy, Austria, Poland, Sweden and the US. 48 WORLD OF INDUSTRIES

PRODUCT NEWS Modular platform of automation panel family One of the global leader of industrial automation, B&R, is expanding its automation panel family with a new series of widescreen formats from 7” WVGA to 24” Full HD. Automation Panel 1000 devices offer easy and flexible mounting options. The slender design is available with a single-touch or multitouch screen. Adding a PC unit turns an Automation Panel into a full-fledged Panel PC with scalable processing power. The core component is the panel itself, which is available in widescreen variants ranging from 7” WVGA to 24” Full HD. Adding a modular SDL/DVI receiver makes it an operator terminal. When using SDL3 digital signal transmission technology, it is even possible to bridge more than 100 m between terminal and PC. Standard Ethernet cables are used. Panel PCs offer scalable computing power from Intel Atom up to Core i7. www.br-automation.com Tablet PC for mobile industrial applications The Simatic ITP1000 industrial tablet PC is currently one of the fastest tablet PCs on the market. It has a projective-capacitive 10.1-inch Multitouch display, the latest Intel Core i5 Skylake processor technology, and the Trusted Platform Module. Designed for industrial use, the tablet PC is especially suitable for service, production, measuring and testing, as well as for operator control and monitoring and supports Windows 7 and Windows 10. With many different interfaces and well-thoughtout product features, the Simatic ITP1000 is versatile, can be used everywhere, and can be integrated in both new and existing plant concepts. To handle challenging tasks, a high-performance chip set with the latest Intel Skylake CPU technology is used. The DDR4 RAM can be upgraded up to 16 GByte, and a 256 or 512-GByte SSD can also be added to the device. Even customized automation tasks can be handled flexibly with the practical industrial functions – such as RFID, a bar code reader, camera, and six freely programmable function buttons. www.siemens.com chainflex® works ... Servo cable 26 Test million strokes tested 4404 Measuring system cable 66 Test million strokes tested 3479 Moving energy made easy with the world's number 1 for moving cables: ● Largest selection; up to 7 price levels ● From stock, from 1meter, without cutting fees ● Largest test lab in the industry ● Available as an assembled e-chainsystem ® ● Calculate lifetime online www.igus.eu/chainflextest Free Samples: igus ® GmbH Tel. +49-2203-9649-800 info@igus.eu plastics for longer life ® The terms "igus, chainflex, e-chainsystem, plastics for longer life" are legally protected trademarks in the Federal Republic of Germany and, where applicable, in some foreign countries. Visit us: Hannover Messe – Hall 17 Booth H04 Igus.indd 1 14.03.2017 15:08:09 WORLD OF INDUSTRIES 49

- Page 1 and 2: www.world-of-industries.de Hannover

- Page 3 and 4: WELCOME Welcome to the world stage

- Page 5 and 6: 44 52 36 BLOCK I/O MODULES SIMPLIFY

- Page 7 and 8: NEWS AND MARKETS 4 5 Your Global Au

- Page 9 and 10: NEWS AND MARKETS politicians and Tr

- Page 11 and 12: NEWS AND MARKETS tomorrow runs with

- Page 13 and 14: If you want to build the world’s

- Page 15 and 16: NEWS AND MARKETS Poland’s Morawie

- Page 17 and 18: NEWS AND MARKETS IMI Precision Engi

- Page 19 and 20: MACHINE ELEMENTS 01 Igus bearings a

- Page 21 and 22: MACHINE ELEMENTS ence from pilot pr

- Page 23 and 24: Brake Technology 4.0 at Hannover Me

- Page 25 and 26: MACHINE ELEMENTS 01 In the Batumi t

- Page 27 and 28: Dynamic Solutions Expertise. For a

- Page 29 and 30: MACHINE ELEMENTS IEC 61508-3, 7.4.2

- Page 31 and 32: DRIVE TECHNOLOGY Basic data for Nor

- Page 33 and 34: PRODUCT NEWS Fan blades inspired fr

- Page 35 and 36: Floating caliper brake with one-pie

- Page 37 and 38: SENSORS AND MEASUREMENT Both RFID b

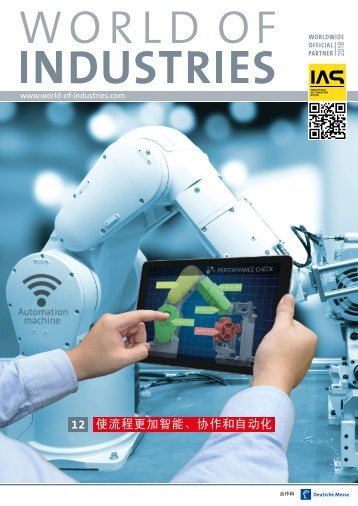

- Page 39 and 40: CONTROL AND DRIVE TECHNOLOGY onstra

- Page 41 and 42: CONTROL AND DRIVE TECHNOLOGY Handof

- Page 43 and 44: INDUSTRIAL COMMUNICATION 01 The Pro

- Page 45 and 46: COMPONENTS AND SOFTWARE integrated

- Page 47: COMPONENTS AND SOFTWARE Industrial

- Page 51 and 52: COMPRESSED AIR NEWS Compressed Air

- Page 53 and 54: ComVac. How can we combine innovati

- Page 55 and 56: 02 Real-time data monitoring is per

- Page 57 and 58: COMPRESSED AIR NEWS New energy-effi

- Page 59 and 60: CONTENT - MARKETING AT ITS BEST BE

Inappropriate

Loading...

Mail this publication

Loading...

Embed

Loading...