world of industries 8/2016 (EN)

- Text

- Industrial

- Logistics

- Industries

- Automation

- Manufacturing

- Solutions

- Products

- Components

- Warehousing

- Valves

Germany plays a key role

Germany plays a key role in “Industrie 4.0” INDUSTRIAL AUTOMATION INDIA The advancing digitization and networking of production is also changing value chains in industry – this transformation is known in Germany as Industrie 4.0 or IIoT worldwide. But why is Germany playing the key role in this topic? The term “Industrie 4.0” stands for the interaction of three factors: the digitization and integration of vertical and horizontal value chains, the digitization of products and service offerings, and new digital business models. This results in new solutions being created for the Internet of Things, Services and People. The digitization and integration of the value chains means that data from various phases of the product life cycle is available across companies – from the quotation process through to production and on-site service. All companies in the value creation network can thus access the data they need at any time. For example, mechanical engineers receive the component supplier data that is relevant to them, and users integrate the mechanical engineers’ digital construction data into the design of their factory buildings in advance. This results in increased efficiency, which benefits all those involved. For this purpose, however, information regarding products and services must be available in digital format. The digitization of products and services means the complete virtual description of services and products. However, end-to-end digitization also facilitates completely new digital business models. Services and offerings are created that bring the user decisive advantages using data that is, for instance, in the cloud: examples are more efficient and predictive maintenance of equipment. The German electrical industry plays a key role when it comes to implementing smart factories in the manufacturing and smart plants in processing industry. Its know-how, equipment and systems are the enabler for the transition to digital production that transcends geographical boundaries. ZVEI member companies undoubtedly have the knowledge of manufacturing and business processes in the manufacturing and process industry as well as the expertise to produce Industrie 4.0 technologies. Automation forms the interface between machines and production in the Internet of Things, Services and People. It both equips and uses Industrie 4.0. For this reason, a holistic understanding of Industrie 4.0 developed here first. If you want to know, how Industrie 4.0 can change the industrial production and make it more flexible, safety and cheaper – please read our following notes. The downloads are worthwhile! www.zvei.org 56 World of Industries 8/2016

NEWS AND MARKETS What is RAMI 4.0? To create a uniform basis for Industrie 4.0, ZVEI has teamed up with its partners to develop RAMI 4.0, the reference architecture model for Industrie 4.0. But what does it mean? Find out in the Video: www.Bit.ly/1TjQ4dV Two papers – one goal Product criteria for Industrie 4.0 technologies: Which properties does a product need in order to be Industrie 4.0 compatible? The Reference Architecture Model Industrie 4.0 and the Industrie 4.0 component provide a basic method and orientation. Read more: www.bit.ly/1TZjBvx On the way to the smart factory – the electrical industry is pushing forward: The German electrical industry plays a key role when it comes to implementing smart factories in the manufacturing and smart plants in processing industry. This position paper deals with what needs to be done now in order to really implement Industrie 4.0. Read more: www.bit.ly/1YC88Dv Your Global Automation Partner All in full view! The Cabinet Guard The IMX12-CCM in its 12.5 mm DIN rail housing monitors the degree of protection and the environment variables in cabinets and protective housings After simple teaching on the spot, the device reports incorrectly closed doors as well as excesses of temperature and indoor humidity Condition monitoring, easy to install and retrofittable, thanks to intrinsically safe 2-wire transducer supply-interface, even in the Ex-area www.turck.com/ccm

- Page 1 and 2:

08/2016 www.en.engineering-news.net

- Page 3 and 4:

WELCOME Dear Readers, Today, Manufa

- Page 5 and 6: 54 66 50 MILLING HEADS WITH AN IO-L

- Page 7 and 8: Pilz opens a subsidiary in Singapor

- Page 9 and 10: NEWS AND MARKETS high as America, b

- Page 11 and 12: Increase your warehouse capacity Bu

- Page 13 and 14: NEWS AND MARKETS in the overall tax

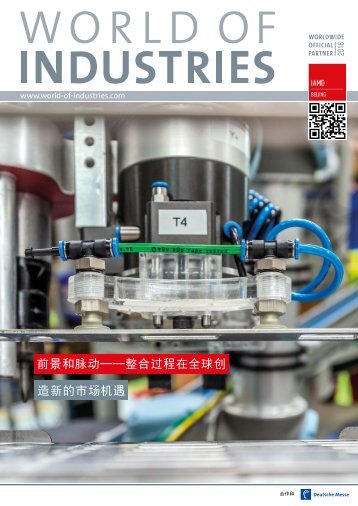

- Page 15 and 16: NEWS AND MARKETS For visitors comin

- Page 17 and 18: Antriebstechnik MOTION, DRIVE & AUT

- Page 19 and 20: MACHINE ELEMENTS MULTIMEDIA CONTENT

- Page 21 and 22: MACHINE ELEMENTS Mayr power transmi

- Page 23 and 24: MACHINE ELEMENTS 02 Insides of the

- Page 25 and 26: Dynamic Solutions Expertise. For a

- Page 27 and 28: PRODUCT NEWS Edge protection profil

- Page 29 and 30: MACHINE ELEMENTS 02 ContiTech’s n

- Page 31 and 32: MACHINE ELEMENTS bubbles of air tha

- Page 33 and 34: MEASUREMENT AND CONTROL in the VP-X

- Page 35 and 36: MACHINE ELEMENTS 01 The new generat

- Page 37 and 38: DRIVE TECHNOLOGIES BWIL and machine

- Page 39 and 40: INDUSTRIAL AUTOMATION INTERNATIONAL

- Page 41 and 42: SENSORS AND MEASUREMENT damaged dia

- Page 43 and 44: SENSORS AND MEASUREMENT More powerf

- Page 45 and 46: MACHINE VISION Allied Vision’s Pr

- Page 47 and 48: MACHINE VISION NKL’s new lens pac

- Page 49 and 50: CONTROL AND DRIVE TECHNOLOGY 02 01

- Page 51 and 52: INDUSTRIAL COMMUNICATION Photo left

- Page 53 and 54: INDUSTRIAL COMMUNICATION About Pepp

- Page 55: INDUSTRIAL COMMUNICATION Layered Se

- Page 59 and 60: INDUSTRIAL COMMUNICATION Advantages

- Page 61 and 62: and Intralogistics INTRALOGISTICS I

- Page 63 and 64: GLOBAL BUSINESS As some of the reas

- Page 65 and 66: SOME THINK DELIVERY ERRORS ARE INEV

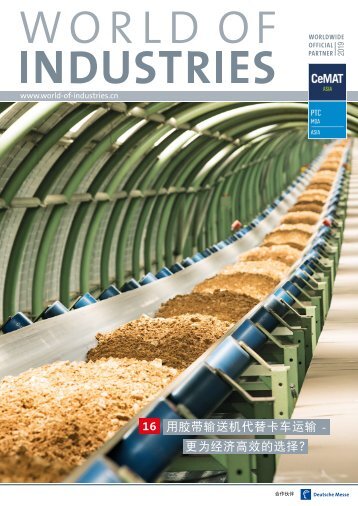

- Page 67 and 68: BULK MATERIAL HANDLING comprising a

- Page 69 and 70: INDUSTRIAL TRUCKS Using the Retrak

- Page 71 and 72: WAREHOUSING The Belgian company gro

- Page 73 and 74: More endurance. More performance. 1

- Page 75 and 76: Product News User-friendly like a s

Inappropriate

Loading...

Mail this publication

Loading...

Embed

Loading...