world of industries 1/2017 (EN)

- Text

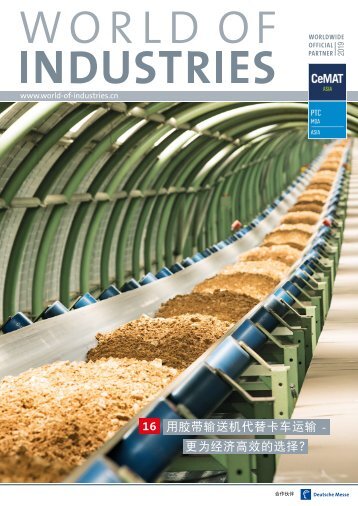

- Logistics

- Intralogistics

BLG recognizes a great

BLG recognizes a great potential in the Malaysian market WORLD OF INDUSTRIES The core competence of BLG Logistics is in automotive, contract and container logistics, where we supply fully integrated logistical system solutions. BLG is active in 15 countries around the world, and over the past 16 years has developed from a locally active enterprise in Northern Germany to a global logistics service provider. Today, our company employs over 16,000 people in Europe, America, Africa and Asia. Its scope is extended even further by cooperation agreements, subsidiaries and shareholdings. In 2006 we expanded our range through a joint venture in Malaysia: BLG Logistics and the Malaysian logistics service provider MISC Integrated Logistics Sdn Bhd (MILS), a subsidiary of the Petronas Group, teamed up to win a tender for a German carmaker. Since then, our joint venture has been performing plant logistics functions for our customer in Pekan, on the east coast of Malaysia. Our previous partner changed in 2016, so that BLG is now working with the logistics service provider Swift Haulage SDN BHD as its new joint venture partner. This new joint venture is doing business under the name BLG Swift Logistics Sdn Bhd, and continues to perform plant logistics for our customer in Pekan just as before. We complement each other ideally: Swift contributes expertise in the areas of transport and forwarding, while BLG is a recognized expert for cross-sector management of logistics warehouses. When we entered the Malaysian market in 2006, a lot of OEMs were looking for logistics partners with a high level of expertise locally. Thus, we recognized early on that the rapidly growing Southeast Asian region represented an attractive and strategically advantageous market for BLG. The excellent infrastructure and market situation, Malaysia’s political and economic stability and this nation’s extremely internationally-oriented culture were ideal prerequisites for entering this market. The developments of the past years have confirmed our estimation of the market. Since our joint venture was founded in 2006, we’ve succeeded in acquiring many top-level customers, and currently employ over 80 people at four locations. In Pekan, we manage our customer’s vehicle distribution center (VDC), with space for around 1,000 cars and trucks: we receive the vehicles from production, move them to their storage location and organize the transport of the vehicles to Malaysian dealers. We are convinced that Malaysia will remain an important market in the Southeast Asia region In Port Klang, our joint venture operates its own VDC for renowned international car makers. This facility also includes a bonded warehouse. The warehouse and outdoor areas can accommodate up to 2,000 vehicles, which are stored, maintained and serviced by BLG Swift Logistics. Our joint venture also transports the vehicles to dealers throughout Malaysia. Besides these locations, BLG Swift also operates in Kulim, in northeastern Malaysia. Just as in Pekan, we provide factory logistics for a major customer from the automotive industry, and perform storage, maintenance and technical services in a facility that accommodates over 400 vehicles. We also organize domestic transport to the respective dealers. The fourth pillar of BLG Swift Logistics is located in Glenmarie, where we operate a spare-parts warehouse for the Hyundai, Ford and Jaguar Land Rover brands of our customer Sime Darby Motors that comprises 5,000 square meters of indoor warehouse space. We also deliver the spare parts in the Kuala Lumpur region using our own trucks. Last year, we posted moderate growth across our entire portfolio of current business. For 2017, our focus is on developing our joint venture further and achieving growth through new business. At present, our customer structure ties us very closely to the automotive industry. Thus, we are aiming to expand our customer portfolio to further industries in the near future. We are convinced that Malaysia will remain an important market in the Southeast Asia region, in spite of the current difficult economic situation. Despite some uncertainty with respect to the political and economic development in the coming year, we are entirely optimistic about 2017 and how it will develop for BLG, and we are working towards further growth. www.blg-logistics.com Thomas Leiber, previously Director Overseas East and responsible for the activities of BLG L Logistics in Asia, assumed the general management of the BLG joint venture on site in Malaysia at the end of 2016, relocating from Bremen to BLG’s Malaysian headquarters in Port Klang 12 WORLD OF INDUSTRIES

Product News Safely reaching the right height The newly developed FMA series flat form lifting tables from Flexlift are based on the narrow lifting tables from the “FM” series. However, the current design has additional runners along both longitudinal sides on to which the transport truck is driven when the lifting table is lowered. This can be implemented without any problems, as it only has to be driven on to the 4 to 5 mm thick metal runners. Recesses, suitable for two of the truck wheels, are located in both of the runners. The truck is positioned correctly once the wheels are located in these recesses. If the lifting table is now moved upwards, the wheels slot into the recesses automatically securing the truck from rolling off the lifting table. The surrounding foot protection strip is extended in the vicinity of the runners so there is no risks of persons becoming trapped when the lifting table is lowered. www.flexlift.de IE4 level conveyor rollers and motors from a single source With more than 130 employees, the Rollex Group is one of the largest suppliers of components for conveying technology. The main products include driven and non-driven carrier rollers, zero-pressure accumulation system components, storage technology and the corresponding accessories. Rollex has worked with its partner, Momentum Technologies GmbH, to further develop its range of products in the field of drive technology and now also offers highly efficient motors (asynchronous, synchronous, hybrid). The MTS synchronous drum motor is an all-in-one, IE4 level drive component. The drive solution has, for example, been developed for sorters and infeed/outfeed units. The stainless steel design with its oil-free drive can also be used in the food industry. The MTS113 synchronous model has a diameter of 113 mm and is available with a rated power of up to 1 000 W. The MTS82 type drum motor with a diameter of 82 mm and a rated power of up to 380 W is available as a solution for material flow systems with space constraints. The MTS synchronous drum motors are available directly from the factory with or without a rotary encoder and a variety of transmission systems. www.rollex-group.com Dock shelters from Koch-Lagertechnik provide all-round protection To achieve the required environmental objectives, the German furniture dealer, Höffner, is relying on dock shelters from Koch- Lagertechnik at its newly constructed logistic center. The TAS-SK type seals with side parts made of a highly insulating, special foam core reduce the amount of heat that is lost from the hall due to drafts. With the help of compression slats, the vertical skirting presses itself accurately against the outside of the vehicles and transfer platforms. The dock shelters have in part been fitted with double, horizontal curtains and extra recesses to largely prevent warm air escaping upwards out of the hall. The curtains are split and staggered vertically at intervals of 20 cm, which in addition to their heavy weight ensures that they push against the contours of the relevant vehicle. Within the side parts of the dock shelter seal, the otherwise customary metal parts have been replaced with a 10 cm thick foam core thus ensuring that trucks that approach incorrectly do not bend or break anything. www.koch-lagertechnik.com Self-driving forklift truck – TORsten from Torwegge The omnidirectional transport vehicle “Torsten” from Torwegge not only moves loads of up to seven tons autonomously through the production and logistic halls but also navigates its way through independently. The automated transport vehicle is equipped with its own sensors and is not connected to an inductive or optical tracking system. The design does not include a drawbar thus ensuring that the industrial truck can turn on the spot and drive in all directions which is very useful during assembly work. The assembly technician does not need to move around the component but can instead rotate the component. The flat and compact design of the industrial truck including its 1150 × 700 mm large platform enables individual attachments to be assembled. This enables the automated transport vehicle to transport pallet cages through to Euro pallets, individual components and anything else that may need moving from A to B within the warehouse and production halls. The vehicle orientates itself via the in-built sensor system and a 3D plan of the hall in which it moves around at a speed of up to 0.8 m/s. www.torwegge.de WORLD OF INDUSTRIES 13

- Page 1 and 2: www.engineering-news.net Making the

- Page 3 and 4: TABLE OF CONTENT 05 EDITORIAL 06 WO

- Page 5 and 6: WELCOME Dear Readers, Indonesia, th

- Page 7 and 8: 1 Still establishes direct distribu

- Page 9 and 10: GLOBAL BUSINESS changing purchasing

- Page 11: GLOBAL BUSINESS The AEC, implemente

- Page 15 and 16: High logistics costs Now is the rig

- Page 17 and 18: GLOBAL BUSINESS society. Digitizati

- Page 19 and 20: INDUSTRIAL TRUCKS companies should

- Page 21 and 22: WAREHOUSING Amul is much more than

- Page 23 and 24: WAREHOUSING David Eisenhut, Directo

- Page 25 and 26: CRANES AND HOISTS newly developed e

- Page 27 and 28: CRANES & HOISTS Image: All function

Inappropriate

Loading...

Mail this publication

Loading...

Embed

Loading...